Technician safety equipment is vital in automotive workshops for worker protection during tasks like paint and dent repair. Effective training involves written materials, practical demonstrations, role-playing, and regular refreshers. Continuous learning ensures adherence to protocols, regulations, and best practices, fostering a culture of safety through open communication and accessible resources.

New employees in technical roles often rely on specialist equipment to perform their tasks safely and efficiently. This article delves into effective strategies that shops employ to train newcomers in using technician safety equipment. We’ll explore comprehensive overviews of essential gear, proven training methods, and continuous learning practices to ensure new technicians are equipped for safe and compliant operations from day one. Understanding and mastering technician safety equipment is crucial for both employees and employers alike.

- Understanding Technician Safety Equipment: A Comprehensive Overview

- Effective Training Methods for New Employees

- Ensuring Continuous Learning and Compliance After Initial Training

Understanding Technician Safety Equipment: A Comprehensive Overview

Technician safety equipment is an essential aspect of any automotive workshop or collision repair centre. It encompasses a wide range of tools and garments designed to protect workers from potential hazards during various tasks, such as car paint repair, car dent repair, and other specialized services. Understanding the purpose and correct usage of each piece of equipment is crucial for new employees.

A comprehensive overview should include familiarizing technicians with personal protective equipment (PPE), which may include gloves, safety goggles, ear protection, respirators, and aprons. Additionally, training should cover specific tools like impact wrenches, sanders, and paint spray guns, ensuring employees know how to operate them safely. For instance, in car dent repair, the right use of a pneumatic hammer requires instruction to prevent accidents and ensure the technician’s well-being.

Effective Training Methods for New Employees

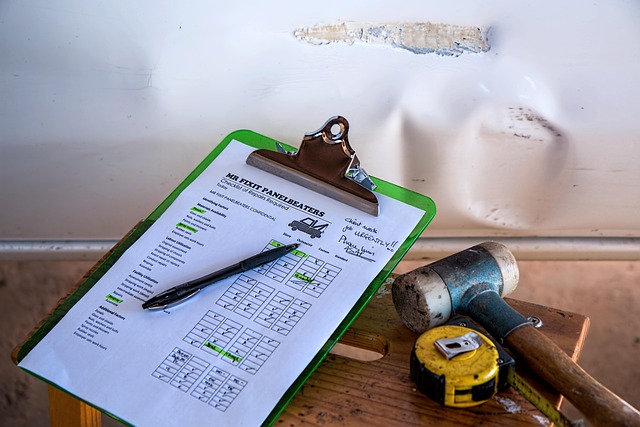

When training new employees on technician safety equipment usage, shops should leverage a combination of interactive and hands-on methods to ensure comprehension. Starting with comprehensive written materials that outline each piece of equipment’s purpose, operation, and safety protocols provides a foundational understanding. This should be followed by practical demonstrations led by experienced technicians, allowing newcomers to witness the equipment in action and ask questions in real-time.

Role-playing scenarios, mimicking common tasks like auto painting or car dent repair, can significantly enhance learning. These simulations not only test employees’ understanding but also help them internalize safety protocols under pressure. Additionally, regular refreshers and ongoing support through mentoring programs ensure that new hires stay aligned with best practices in auto maintenance, especially as they gain experience.

Ensuring Continuous Learning and Compliance After Initial Training

After initial training on technician safety equipment usage, continuous learning and compliance are paramount to maintain a safe working environment. Regular refresher courses and workshops ensure that employees stay updated with the latest safety protocols and regulations, especially as technology and industry standards evolve. These ongoing sessions can cover specific topics like proper use of personal protective equipment (PPE), handling hazardous materials, or operating advanced tools and machinery used in auto body painting, vehicle dent repair, and auto glass repair.

Shops should also implement a culture of open communication and feedback. Encouraging employees to ask questions, report safety concerns, and share best practices fosters an environment where safety is prioritized. Additionally, providing accessible resources such as online modules, digital guides, or even peer mentoring can supplement formal training programs. This multi-faceted approach ensures that technician safety equipment usage remains a top priority, promoting a culture of continuous improvement and compliance within the organization.

Shops training new employees on technician safety equipment usage must go beyond initial instruction. Effective programs combine comprehensive overviews of gear, interactive demonstrations, and ongoing practice sessions to ensure comprehension and adherence to safety protocols. By prioritizing continuous learning, shops can foster a culture where every technician feels empowered to use the right equipment correctly, ultimately enhancing workplace safety.