Smart Wearables: Revolutionizing Technician Safety Equipment for the Future

The current technician safety equipment relies on traditional gear lacking real-time data integratio…….

In the ever-evolving landscape of technology and industry, ensuring the safety of technicians is paramount. Technician safety equipment (TSE) refers to a range of specialized gear and apparatus designed to protect workers from potential hazards during their operations. This article aims to provide an in-depth exploration of TSE, its role, impact, and future trajectory. By delving into various aspects, we will equip readers with valuable insights into the critical equipment that safeguards technicians across diverse sectors.

Technician safety equipment is a collective term encompassing various tools, garments, and protective devices worn by technicians to mitigate risks associated with their work environments. It includes but is not limited to items such as hard hats, safety goggles, gloves, earplugs, respirators, high-visibility vests, fall protection gear, electrical insulation suits, and heat-resistant clothing. The primary goal of TSE is to minimize the risk of injuries, illnesses, and fatalities in technically demanding jobs.

Historically, the need for TSE emerged as industries became more complex and hazardous. With the advent of new technologies and processes, technicians faced unique challenges, leading to the development of specialized safety gear. Over time, technological advancements have improved the design and effectiveness of TSE, making it an indispensable part of modern workplace safety protocols.

The importance of technician safety equipment is not confined to any specific region; it has a global impact. International organizations and regulatory bodies have recognized the need for standardized safety standards, ensuring that technicians worldwide receive adequate protection. For instance, the International Labour Organization (ILO) plays a pivotal role in setting guidelines and promoting safe working conditions, including the provision of TSE.

Key trends shaping the TSE market include:

The global technician safety equipment market is a significant economic sector, influenced by various factors:

| Factor | Impact |

|---|---|

| Industry Growth: The expansion of industries such as construction, manufacturing, healthcare, and renewable energy drives the demand for TSE. | Market Expansion: As these sectors grow, so does the need for specialized safety equipment, creating new market opportunities. |

| Regulatory Compliance: Strict labor laws and safety regulations in many countries mandate the use of TSE, ensuring a steady demand. | Compliance-Driven Innovation: Companies innovate to meet evolving regulatory standards, leading to improved TSE designs and technologies. |

| Cost-Effectiveness: Affordability is a critical factor, especially for small businesses and emerging markets. | Competitive Pricing: Manufacturers compete to offer cost-effective solutions without compromising quality, making TSE more accessible. |

| Technology Integration: The integration of technology adds value but also increases costs. | Premium Pricing: High-tech TSE often comes at a premium, catering to industries requiring advanced safety features. |

Technological progress has significantly enhanced technician safety equipment, opening new possibilities for improved protection and efficiency. Here are some notable advancements:

Governing bodies worldwide have implemented policies and regulations to ensure the safe use of technician safety equipment. These frameworks provide guidelines for equipment standards, training requirements, and workplace safety protocols. Key examples include:

Despite its significance, technician safety equipment faces several challenges and criticisms that require attention:

Solutions and Strategies:

Singapore’s construction industry, known for its rapid growth and stringent safety standards, has implemented innovative TSE solutions. The country’s authorities introduced mandatory fall protection systems for all construction sites, including advanced guardrails, safety nets, and personal fall arrest systems. This initiative significantly reduced fall-related injuries and fatalities, setting a benchmark for other countries.

The COVID-19 pandemic posed unique challenges for healthcare workers, requiring them to adapt their safety gear to protect against airborne transmissible diseases. Medical professionals adopted specialized respirators with higher filtration efficiencies, such as N95 masks, and implemented additional protective measures like face shields and isolation gowns. This rapid adaptation demonstrated the importance of TSE in responding to unforeseen crises.

The growing renewable energy sector presents challenges for technicians working in remote locations. To address this, companies have introduced comprehensive TSE packages tailored to off-grid operations, including ruggedized communication devices, advanced weather protection gear, and specialized tools for remote troubleshooting. These measures ensure the safety of technicians while enhancing productivity.

The landscape of technician safety equipment is poised for further growth and innovation. Here are some key trends shaping its future:

Technician safety equipment plays a pivotal role in ensuring the well-being of technicians across various sectors. From its historical evolution to the latest technological advancements, TSE has come a long way. As industries continue to grow and face new challenges, the importance of robust TSE protocols cannot be overstated. By addressing global trends, economic considerations, and emerging technologies, we can shape a future where technician safety is optimized, and accidents are minimized.

Q: What is the primary purpose of technician safety equipment?

A: The primary purpose is to protect technicians from potential hazards in their work environments, ensuring their safety and well-being.

Q: How do I choose the right safety gear for my specific job?

A: Consider factors like task requirements, environmental conditions, and personal comfort. Consult industry standards and seek expert advice to make informed choices.

Q: Are there any global standards for technician safety equipment?

A: Yes, organizations like ISO (International Organization for Standardization) and the ILO establish guidelines and standards for TSE to ensure consistency and quality worldwide.

Q: Can technology improve the effectiveness of TSE?

A: Absolutely! Technological advancements such as smart clothing, augmented reality training, and advanced respirators enhance safety by providing real-time data, improved protection, and immersive learning experiences.

Q: How can I ensure proper maintenance of my TSE equipment?

A: Establish a regular maintenance schedule, follow manufacturer instructions, and keep records. Proper care extends the lifespan of gear and ensures its effectiveness when needed.

The current technician safety equipment relies on traditional gear lacking real-time data integratio…….

Technician safety equipment (TSE) has evolved from protecting against physical hazards to addressing…….

Technician safety equipment is crucial for the automotive industry, ensuring compliance with regulat…….

Protective clothing and specialized gear are essential components of technician safety equipment, sa…….

Auto repair shops face challenges with hazardous materials, heavy machinery, and diverse tasks, posi…….

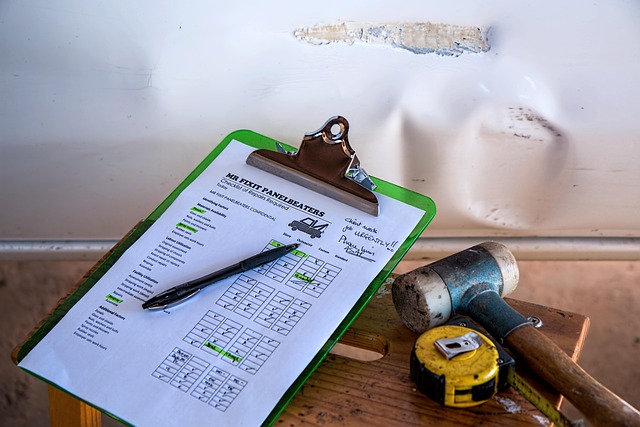

Technician safety equipment (TSE) is vital in auto body work for protecting against hazards, with re…….

Technician safety equipment (TSE) is vital in high-risk industries like auto body repair, where expo…….