Technician safety equipment, including PPE and hearing protection, is vital in automotive repair to guard against chemical splashes, debris, and noise. Effective training involves updating task-specific programs, using interactive methods, and offering diverse delivery. Regular practice drills are crucial for proficiency, enhancing reaction times and decision-making in simulated scenarios, especially in Mercedes-Benz collision repair facilities.

Regular training on the correct use of technician safety equipment is essential for any organization dealing with specialized tools and hazardous environments. This article explores the critical components of staff education, focusing on three key areas: understanding the essentials of technician safety equipment, developing effective training programs, and conducting regular updates and practice drills. By adhering to these practices, companies can ensure their technicians are prepared, skilled, and safe in their daily tasks.

- Understanding Technician Safety Equipment Essentials

- Creating Effective Training Programs for Staff

- Regular Updates and Practice Drills for Optimal Safety

Understanding Technician Safety Equipment Essentials

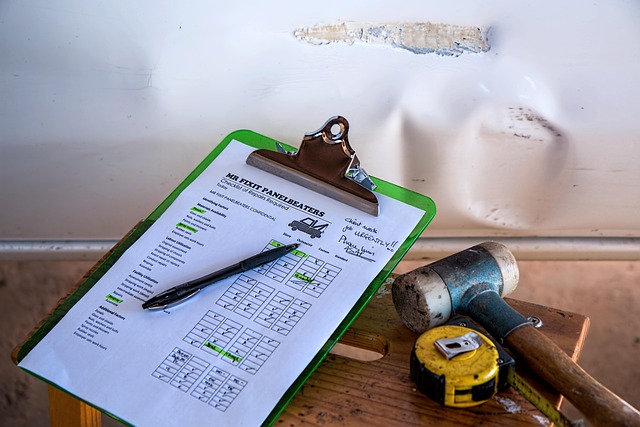

Technician safety equipment is an indispensable aspect of any automotive repair or collision center. It encompasses a wide range of tools and gear designed to protect workers from potential hazards, including chemical splashes, flying debris, and noise exposure. Understanding the essentials of this equipment is crucial for ensuring both staff safety and operational efficiency.

Each piece of technician safety equipment serves a specific purpose in mitigating risks associated with various tasks, such as welding, painting (car paint services), and mechanical repairs. For instance, personal protective equipment (PPE) like gloves, goggles, and respirators are fundamental to safeguarding against chemical fumes, sparks, and particles that could cause injuries. Additionally, hearing protection is vital for mitigating noise exposure during power tools operation, a common occurrence in body shop services environments. Regular training on the correct use and maintenance of these safety equipment items is essential to create a safe and productive workspace.

Creating Effective Training Programs for Staff

Effective training programs for staff on technician safety equipment should be comprehensive, tailored to specific tasks, and regularly updated. Start by assessing the unique risks associated with your operations, such as those involved in auto painting or vehicle paint repair, and frame straightening. Design modules that cover not just donning and doffing procedures but also the importance of each piece of equipment in mitigating risks. Interactive elements like demonstrations, role-plays, and practical exercises can enhance learning retention.

Utilize a variety of delivery methods, including online courses, workshops, and mentoring sessions, to cater to different learning styles. Incorporate real-world scenarios relevant to your industry. Regular refresher courses and periodic evaluations can ensure staff stay proficient in using technician safety equipment properly. This proactive approach not only reduces accidents but also fosters a culture of safety within your organization.

Regular Updates and Practice Drills for Optimal Safety

Regular updates and practice drills are essential components of any comprehensive safety program for technicians working in car body shops or fleet repair services, such as Mercedes-Benz collision repair facilities. Keeping up with the latest advancements in technician safety equipment ensures that staff members are using the most effective and secure tools available.

These regular sessions should include hands-on practice drills to familiarize technicians with new equipment and reinforce proper usage techniques. By regularly engaging in simulated scenarios, workers can hone their skills, improve reaction times, and make informed decisions in high-pressure situations. Such proactive measures contribute significantly to the overall safety culture within these facilities, ultimately reducing risks associated with the handling of heavy machinery and hazardous materials commonly encountered in collision repairs.

Regular training sessions on the correct use of technician safety equipment are essential for maintaining a robust safety culture. By understanding the essentials, creating effective programs, and conducting regular practice drills, organizations can ensure their staff are equipped to handle potential hazards. Continuously updating knowledge and skills fosters confidence and empowers technicians to work safely and efficiently, ultimately contributing to a safer work environment and better outcomes.