Technician safety equipment (TSE) is vital in high-risk industries like auto body repair, where exposure to machinery, tools, and chemicals is common. High-quality TSE, including gloves, goggles, ear protection, and robust clothing, significantly reduces accident risks, boosts productivity, and prevents expensive downtime. Prioritizing safety is both a regulatory requirement and strategic investment in technical fields, fostering job satisfaction, retention, and a culture of responsibility. Investing in up-to-date TSE proactively prevents work-related injuries, safeguarding technicians' health while enhancing overall workplace performance.

Investing in high-quality technician safety equipment is not just a prudent step, but an essential one. In the fast-paced world of technical work, where risks are ever-present, proper gear can be the difference between accident and success. This article explores the multifaceted benefits of prioritizing safety, from preventing injuries and boosting productivity to long-term cost savings, enhanced employee morale, and adherence to regulatory standards. By understanding the value of quality technician safety equipment, businesses can foster a safer, more efficient, and culturally positive work environment.

- The Role of Technician Safety Equipment in Preventing Injuries and Improving Productivity

- – The importance of safety in technical fields

- – Types of equipment that can prevent common work-related injuries

The Role of Technician Safety Equipment in Preventing Injuries and Improving Productivity

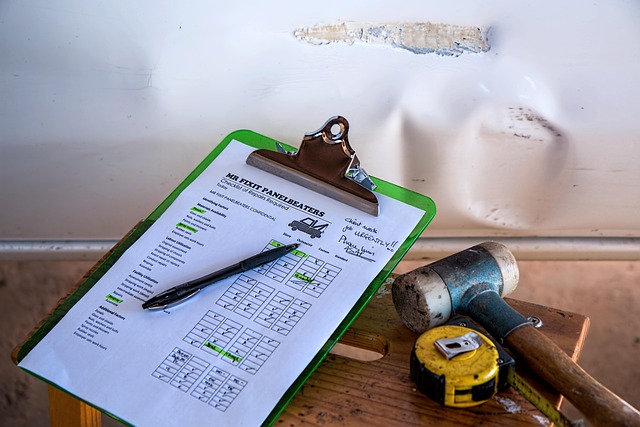

Technician safety equipment plays a pivotal role in preventing injuries and enhancing productivity on the job. In industries such as auto body repair and vehicle body shops, where technicians are exposed to various risks like heavy machinery, sharp tools, and hazardous chemicals, proper protective gear is non-negotiable. High-quality gloves, safety goggles, ear protection, and robust clothing can significantly reduce the likelihood of accidents and injuries.

Investing in top-tier technician safety equipment also contributes to improved work efficiency. When technicians feel secure and protected, they are more likely to focus on their tasks without distraction, leading to higher productivity levels. Moreover, these safety measures help prevent costly downtime due to accidents, ensuring that auto repair services can be delivered smoothly and efficiently.

– The importance of safety in technical fields

In technical fields, safety is paramount as it directly impacts not just the well-being of technicians but also the efficiency and success of operations. Investing in high-quality technician safety equipment (TSE) is a strategic move that goes beyond compliance with regulations. Well-equipped professionals are better prepared to handle risks inherent in their work environments, be it an auto repair shop or a complex auto collision repair facility.

High-quality TSE plays a crucial role in mitigating accidents and injuries related to tasks like paintless dent repair. It ensures that technicians can perform their duties without compromising safety, thereby enhancing job satisfaction and retention rates. Moreover, up-to-date safety equipment contributes to a positive work environment, fostering a culture of responsibility and accountability among employees.

– Types of equipment that can prevent common work-related injuries

Investing in high-quality technician safety equipment is a proactive approach to prevent common work-related injuries, especially for those providing auto repair services or engaging in vehicle body repairs. Personal protective equipment (PPE) such as gloves, eye and face protection, hearing protection, and respirators can significantly reduce the risk of exposure to hazardous materials and substances commonly found in garages and workshops. For instance, technicians working on vehicles with leaks or during certain repairs may be at risk of inhaling toxic fumes; appropriate respiratory gear can mitigate this hazard.

Moreover, proper lifting equipment, sturdy workbenches, and ergonomic tools are crucial for preventing musculoskeletal injuries, which are prevalent among technicians performing vehicle dent repair or intricate bodywork. These safety measures ensure that technicians can work efficiently while safeguarding their health over the long term, thereby enhancing job satisfaction and productivity in auto repair services and related industries.

Investing in high-quality technician safety equipment is a strategic move that goes beyond compliance. It’s an essential step towards fostering a safer working environment, preventing injuries, and enhancing overall productivity. By equipping technicians with the right tools, companies can mitigate risks associated with hazardous tasks, ensuring their workforce remains resilient and capable. In today’s competitive landscape, prioritizing technician safety equipment is not just a moral imperative but a key differentiator in achieving sustained success.